CASE STUDY

Whaleback M103 Drive Upgrade

Improve operations of the M103 Conveyor

| Client & Department | BHP Projects |

| Location | Mt Whaleback Mine Site |

| Project Name | M103 Drive Upgrade |

| Value | 280K |

| Date | 2015 |

| Project Duration | 7 days |

As a continuous improvement project BHP contracted the replacement of the M103 conveyor, drive motor and rotor resistor cubicle to increase the processing of Iron Ore.

Project key deliverables

The Electrical upgrade for this project.

-

De-commission of existing Motor and Drive Assembly

-

Installation of new 6KV Motor and Drive for M103 Conveyor

-

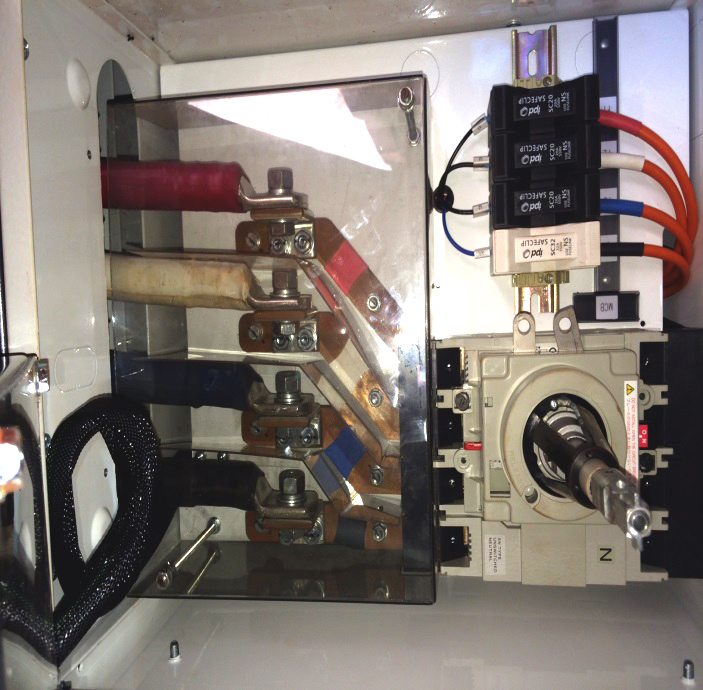

Installation of a new rotor resistor cubicle

-

Modifications to HV CT’s inside the substation Feeder

-

Installation of Feeder Modules

-

Installation of Fibre Optic cable and complete termination

-

Recalibration of the belt weight meter

-

Design and Installation of over 300 metres of Cabling Systems

-

Electrical Commissioning of the Project

Key Challenges

- Completing a Project inside of a limited Shut Down period

- Performing majority of the installation working at Heights

- Working closely with multi-disciplined trades

- Amalgamation of the new equipment with the existing

- Fault finding on existing equipment

The Weststate Advantage

Due to a sound knowledge of BHP specifications and expectations Weststate have a very clear understanding of the importance in completing the project in a safe and timely manner exceeding the client expectations.

-

Extensive knowledge of the BHP systems and procedures

-

A well developed culture among workers who have extensive experience in the mining industry

-

Provide added valued solutions

Other info

- LTI Free Project

- Client feed back was commended by management

- Due to the success of the project Weststate was engaged in repeat business at BHP.